Services

Services Offered

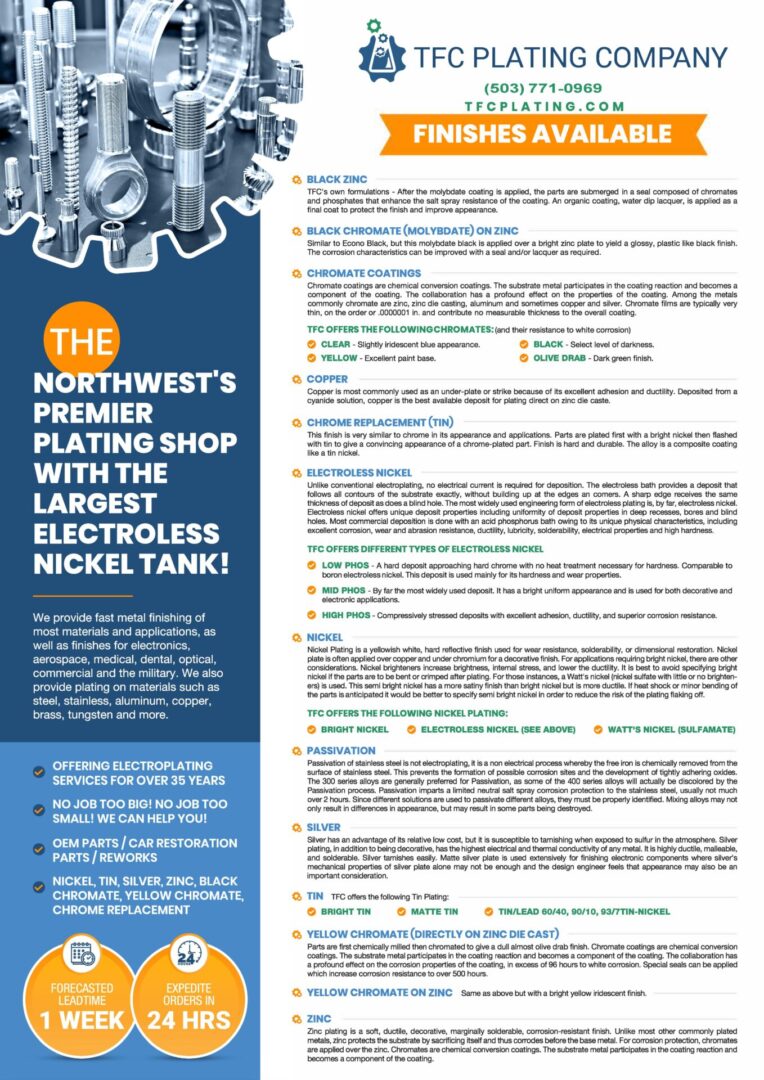

As your premier source for precision metal finishing, we will expertly meet all commercial and plate standards and military specifications.

With decades of experience in metal finishing, we are committed to delivering results that exceed expectations. Our team combines technical knowledge with cutting-edge technology to provide consistent, high-quality finishes.

Every project is rigorously inspected to ensure it meets your specifications and industry standards, guaranteeing long-lasting performance and reliability.

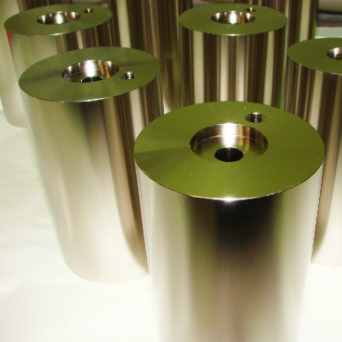

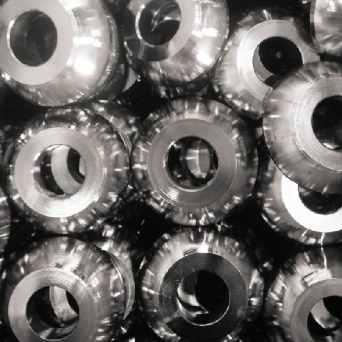

We provide fast metal finishing of most materials and applications, as well as finishes for electronics, aerospace, medical, dental, optical, commercial and the military. We also provide plating on materials such as steel, stainless, aluminum, copper, brass, tungsten and more.

We collaborate with you to understand your needs and provide customized solutions that align with your goals.

At TFC Plating, we specialize in precision metal finishing solutions designed to enhance the durability, performance, and aesthetics of your products. Our expertise in zinc plating and electroless nickel plating ensures exceptional results tailored to the unique demands of industries ranging from automotive to aerospace and beyond. Discover how our services can elevate your manufacturing capabilities and protect your components for the long term.